As a core subsidiary of the OJI Group with over 150 years of history, OJI Functional Materials Company has accumulated knowledge and expertise through extensive experience, and continuously innovates to develop a variety of functional products. We offer a diverse range of products in various fields, "Specialty Papers", "Imaging Media", "Adhesive Products", "Film" and "Nonwoven Fabric" business, that are not only highly functional but also address environmental issues, and continue to strive to support your future with our products. Please find detailed information on our featured products, as a common page among our group companies.

Plastic Reduction, Biomass

Plastic Reduction, Biomass

Plastic reduction problem, originating from marine plastic waste, is now a common major issue worldwide. In response, we are developing environmentally friendly products that reduce burdens by reducing plastics, such as developing paper products with the same function as film, biomass plastic products, and composite materials of biodegradable plastic and cellulose.

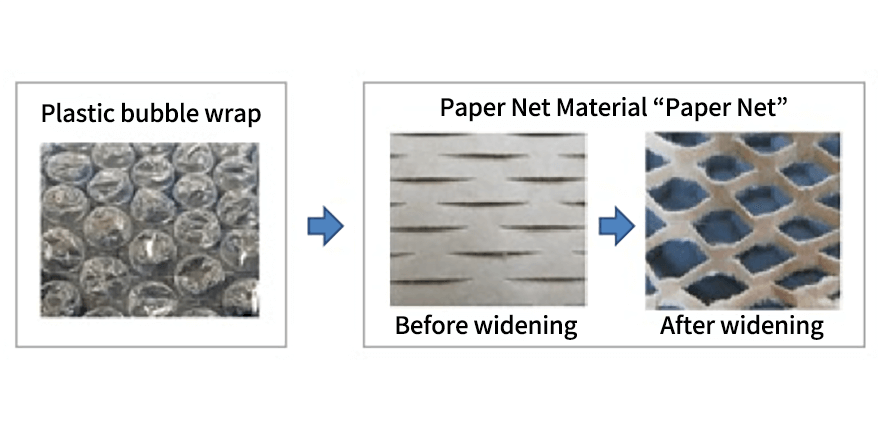

Product

Shock absorbing properties equivalent to existing plastic bubble wrap envelopes, achieved solely with paper.

· Cushion paper stretches like a net to gently wrap the product.

· Made solely of paper and recycled without sorting.

· Thin and space saving before use.

· Not only plastic-free but helpful to redelivery (posting).

· Two models: unbleached paper and coated cardboard as external paper. Coated cardboard model supports more beautiful color printing results. Models with an address window and a separable net are also available as options.

* Patented

* Registered under Plastics Smart scheme

* “Transport packaging category” prize winner in JAPAN PACKAGING CONTEST 2019

* “New creation category” prize winner in the 44th Kinoshita Award (FY2020), sponsored by Japan Packaging Institute

|

|

|

Product

· Recyclable strapping band that can be collected as paper waste together with corrugated containers· With heat seal layers on both sides of a special kraft paper having high paper strength· More flexible than PP bands. easier to put together in disposal.· Can be cut by hand to make unpacking easier· Paper bands are completely pulped in the process of recycling waste paper. So eco-friendly to the environment that it can be recycled together with corrugated containers. |

|

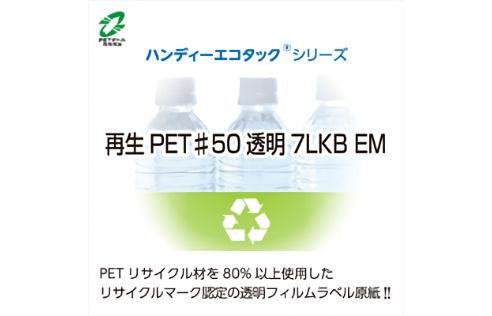

Product

The concept is simple, convenient, and easy to use. Easy way to realize eco-friendly label.

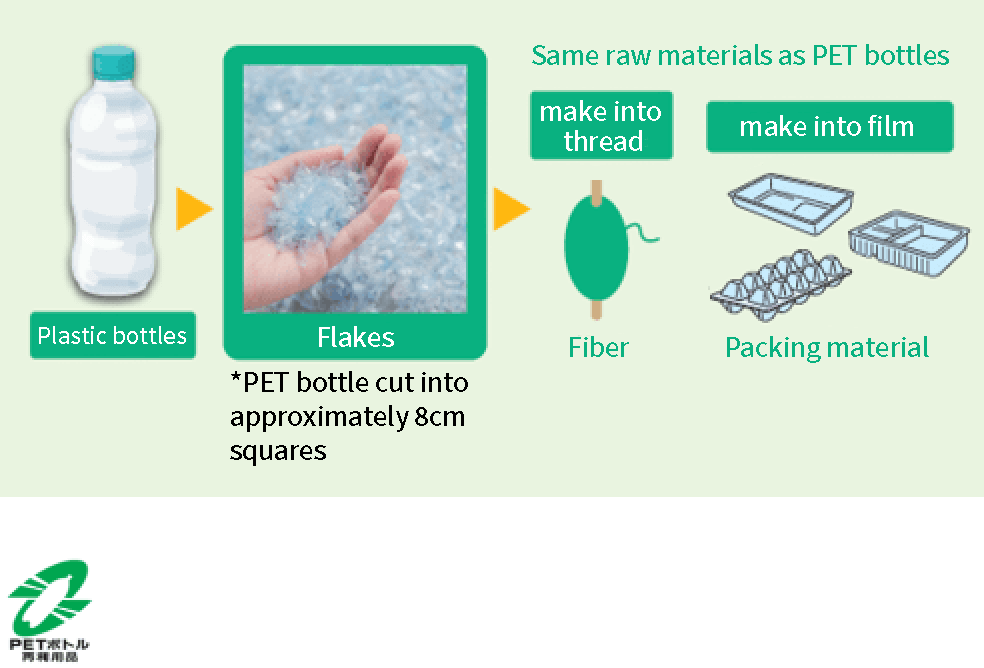

Recycled PET #50 Transparent Type

Made from more than 80% recycled PET.We have obtained the recycling mark.

Adhesive transparent pet film made from recycled PET bottles. Excellent transparency and water-whitening resistance. Good printing suitability for POP labels, etc. |

|

Recycled PET #50 White Type

Made from more than 25% recycled PET.We have obtained the recycling mark.

Polyester film for eco-friendly label, with adhesive processing to white film made from recycled PET bottles. High whiteness and good printability. No tear even when get wet. |

|

RD YUPO #80 Type

Synthetic paper label using 20% less plastic

Significantly reduced plastic usage compared to conventional YUPO By reducing plastic use and CO2 emissions, contribute to reducing environmental impact. ・The adhesive complies with the positive list system of the revised Food Sanitation Act. (Precautions for use: Cannot be used in applications that come in direct contact with food) |

|

EHL64 White / Blue Glassine / EM-C

Made from water-repellent paper laminated with PET and treated with adhesive.Identification mark is PAPER, which enables environmental impact reduction.

・The adhesive complies with the positive list system of the revised Food Sanitation Act. (Precautions for use: Cannot be used in applications that come in direct contact with food) |

|

EHL64 White / Blue Glassine / OR-1

Label made of water-repellent paper, PET laminated, and a repeelable adhesive.Strong adhesive on various materials and re-peelability with little glue residue, so you can peel it off cleanly whenever you want. |

|

Ethical Papers

Washi-style label base paper made by mixing biomass raw materials with waste paper.

Use timber thinned for forest protection and biodiversity conservation, as well as by-products of agricultural crops, such as rice straw and husks, which have been discarded as biomass raw materials, to contribute to nature and environmental conservation. |

|

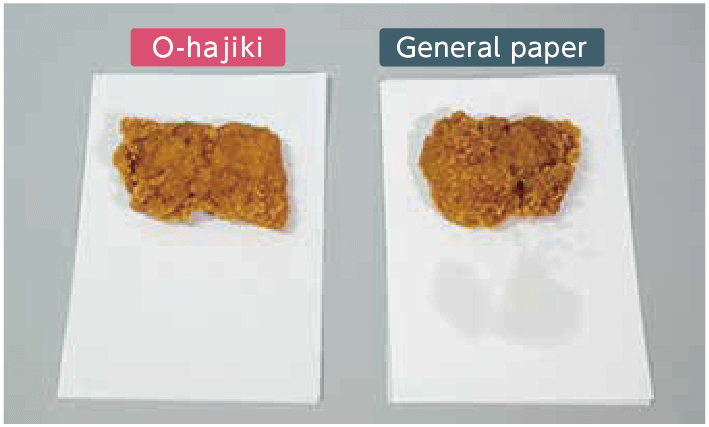

Product

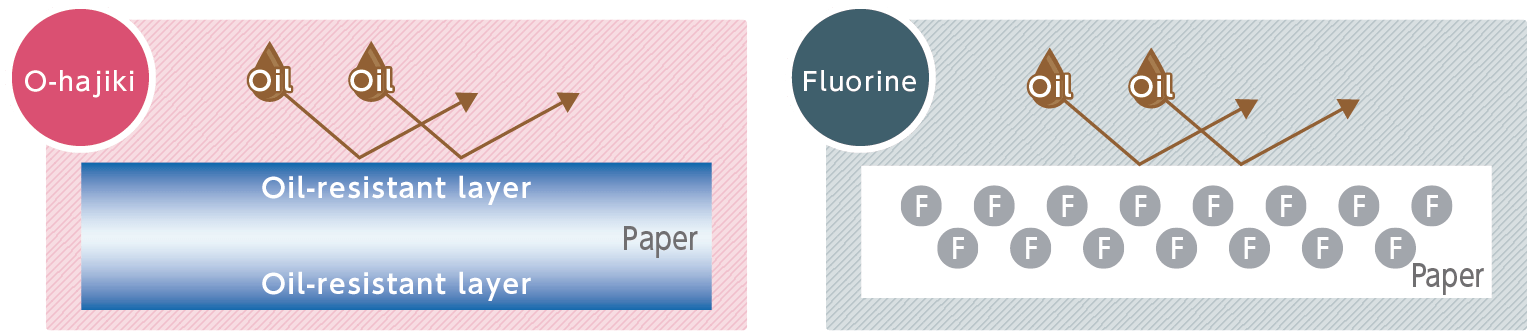

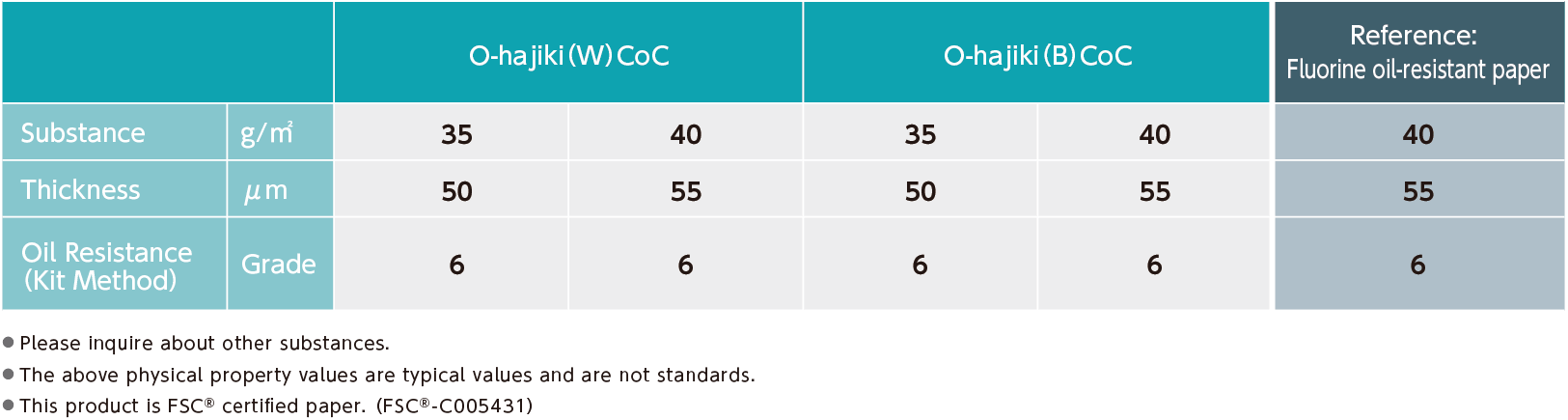

The Oji Group’s coating technology achieves paper material with grease-proof.

Our greaseproof paper uses no fluorine based grease-proofing agents, which are targets the concerns on the environment and health.

Features

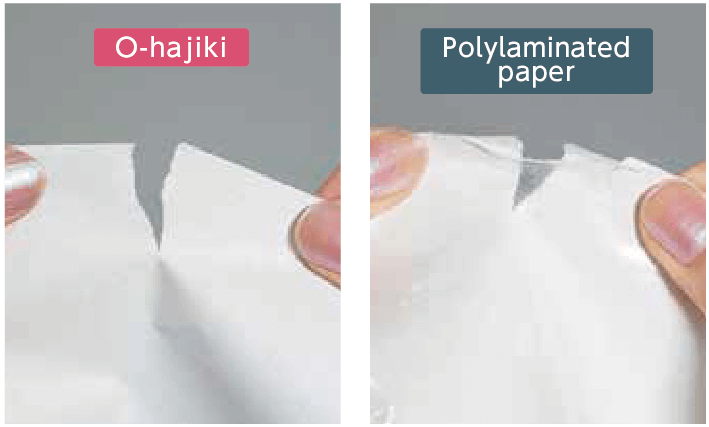

Comparison of oil resistance

O-hajiki shows no oil seaking even in direct contact with fried foods. |

Elimination of plastic

As O-hajiki uses no plastic materials, it can contribute to the elimination and reduction of plastic materials as a replacement for polylaminated paper. |

Mechanism behind oil resistance performance

Examples of applications

|

Packaging and lining paper for french fries, fried chicken, pastries, and other oily foods |

|

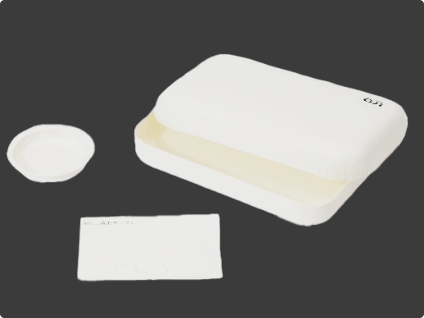

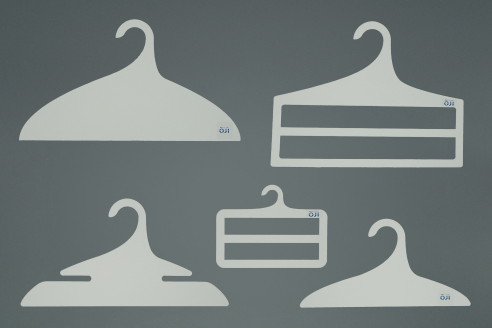

Lineup

Product

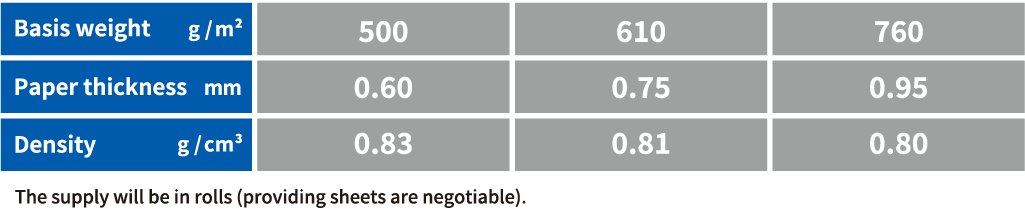

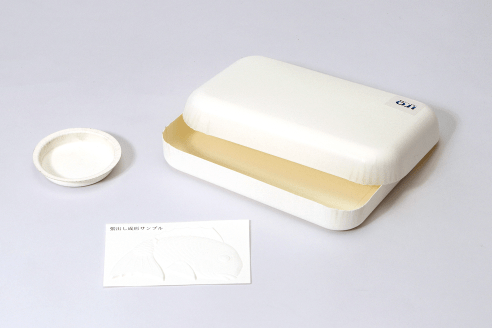

Made from wood pulp, aimed for replacing plastics.

Recyclable and can be printed and used for food applications, e.g. deep-drawn containers, or various household items such as cutlery and hangers.

Feature

1.We can achieve the rigidity required for dishes and containers with a single layer of paper.

2.Fluorescent dye is not used.

3.It can be smoothly and deeply molded with a smooth surface.

4.Due to its smooth moldability, it has excellent lid sealing properties because of its minimum gap occurrence in the upper flange.

Lineup

Examples of molding

|

|

Cooperating Companies: Kuramae Corporation, Nikken Paper Industries Co., Ltd and BIG PLAIN Co., Ltd.

Product

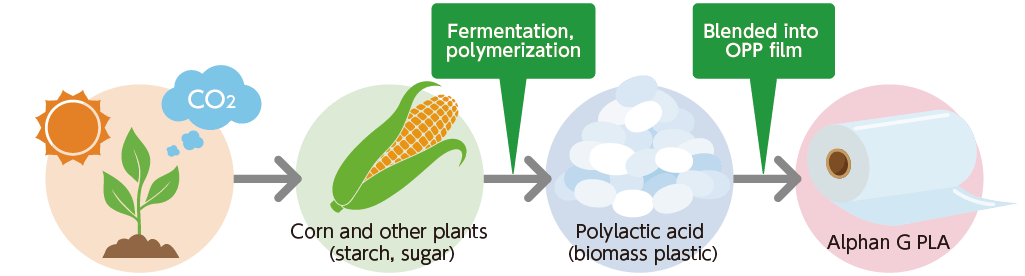

Plant-derived plastic: This polypropylene film is blended with polylactic acid (PLA).

10% of this film is composed of PLA.

Feature

Making full use of feedstock resin blending technology and advanced film forming technology developed through OPP manufacturing, Oji has developed an OPP film made with polylactic acid (PLA). Blending the material with plant-derived PLA reduces the use of petroleum-derived polypropylene.

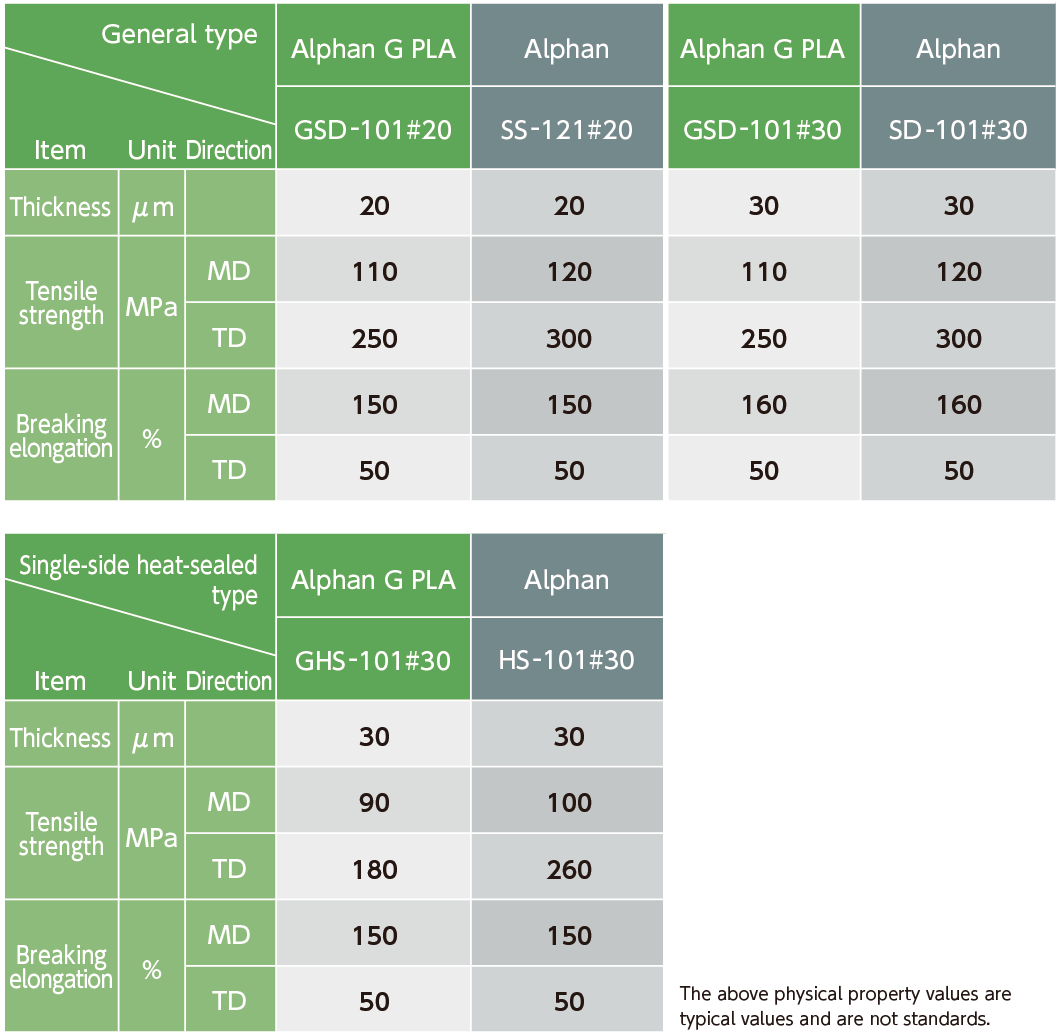

Lineup

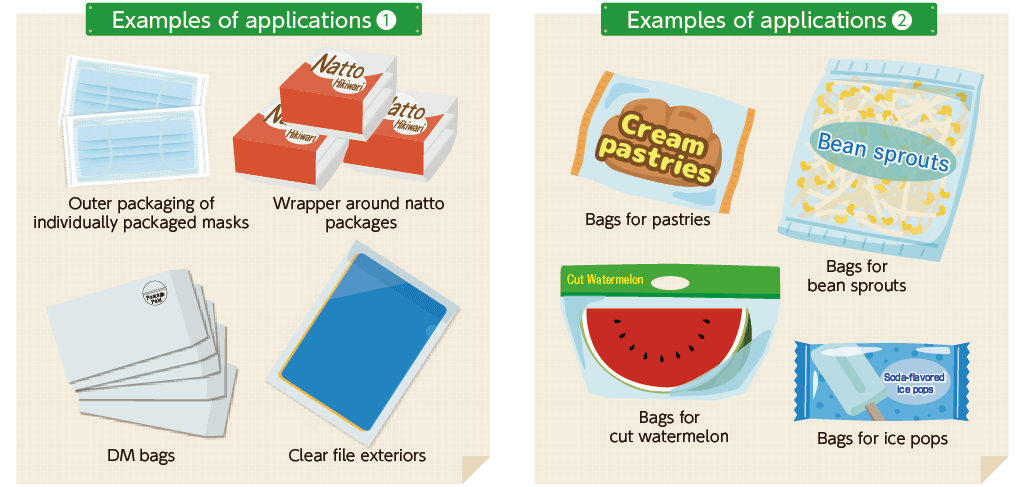

●General types : 20, 30μm (For fusion seal temperature, 400℃ is recommended.)

Applications : Bag making, printing, laminating, etc.

●Single-side heat-sealed type : 20, 30μm

Applications : Pillow packaging, etc.

Physical Properties Table

Examples of applications

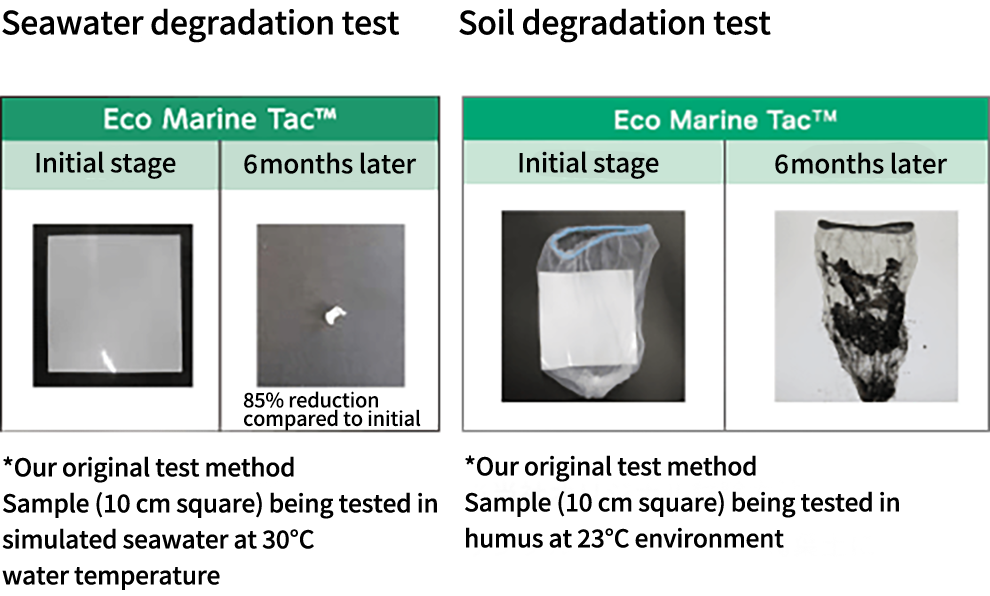

Product

Environmentally friendly film tac is a proposal for Plastic Free.· Naturally degradable biomass film is adopted as surface base material.· Special adhesive is used that barely hampers degradation of the surface base material.· Comparable in printability with PET labels and OPP labels.· Superior to general paper tac in water resistance.* Patent pending * Registered under Plastics Smart scheme * “Technical packaging” prize winner in Japan Packaging Contest 2020 |

|

Product

SILBIO Series is paper-based barrier and packaging material that can replace plastic film.

・SILBIO BARRIER

A barrier coating layer is added onto paper, which restrains the intrusion of oxygen, moisture, and fragrance from outside air. It also prevents the packaged content from diffusing moisture and fragrance.

・SILBIO CLEAR

A paper-based barrier material made with high-transparency paper that shows packaging content.

From foods to daily toiletries, SILBIO CLEAR can be used in a wide range of applications that requires barrier properties.

・SILBIO ALBA

A paper barrier material with light shieling properties through aluminum vapor deposition. Recommended for applications requiring high barrier and opacity properties.

・SILBIO EZSEAL

A heat-sealable paper packaging material that does not require sealant. Recommended for food, on-line shopping and industrial packaging, etc. Please note that it has no barrier properties.

Product

Nonwoven material, made mainly from wood fiber (cellulose fiber), can be thermoformed, sewn, and welded. Graceful texture and cocoon-like feel.

・kinarito

Nonwoven fabrics made mainly from cellulose and PLA, and free of fossil resource-derived plastics.

Biomass Mark 95 certification has been obtained.

・kinarito LEAF

wood fiber consisting more than 60% (some olefin resins are used).

Adopted for biomass slippers(Biomass Mark 80) and Japanese-taste packaging.

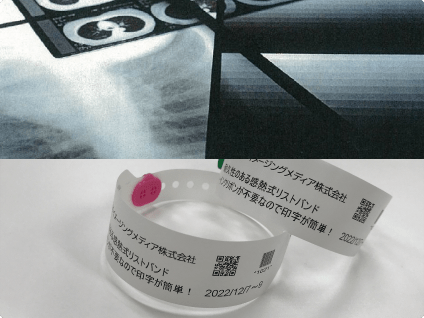

Product

Newly-developed semi-transparent thermal paper, alternative to film.

・Reduce environmental impact by plastic reduction.

・High transparency improving visibility.

・Processable for heat sealing and labeling.

Product

Cellulose fiber reinforced material, contributes to Plastic Free/Plastic Reduction. Our mixing technology enables uniformly dispersing cellulose fiber in the resin matrix, with minimal heat damage, which fully utilize the characteristics of the cellulose fiber. Our lineup includes ToughCel Mat for thermal press molding and ToughCel pellets for injection molding.

Product

For outdoor usage and use in areas expected to get wet.

Made from 100% natural pulp, and despite being a water-repellent paper, can be used for offset printing and laser printing.

Can be used in a variety of fields, incl. outdoor goods, construction sites, and wrapping paper for frozen and refrigerated foods that are prone to condensation.

Recycling, Waste Reduction

Recycling, Waste Reduction

It has been a long time since we started talking about recycling because of the garbage problem, but even today, "recycling" and "waste reduction" are the basis of environmental measures.

As a group of paper companies that are pioneers in recycling, we not only recycle paper, but also develop recycled film products and waste reduction products.

Product

· Recycled PET film is adopted as surface base material.PET material recycled from used and collected plastic bottles is used.· Adhesive with biomass material partly containing plant-derived material.· Recycled PET content depends on product type: 100%/80% or more/25% or more.· Three models: transparent, white and aluminum-deposited· Combined use of recycled and biomass materials is expected to realize CO2 emission reduction.· Transparent recycled film model has a high level of film transparency,while non-laminated direct glassine separator and adhesive blended with biomass material are used.* Registered under Plastics Smart scheme * Certified for the recommendation mark for products recycled from PET plastic bottles |

|

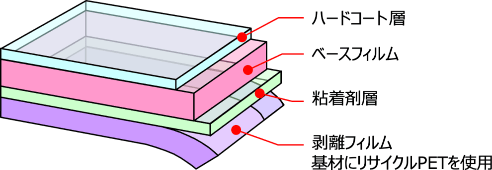

Product

Transparent adhesive film with excellent heat shielding properties・Good for use in interior lamination to window glass for building materials such as houses, commercial buildings, hospitals, convenience stores, pharmacies, etc,・Add heat shielding and combustion resistance properties while maintaining the high transmittance of glass.・Heat shielding performance enables air conditioning load reduction, contributing to energy saving.・Use recycled materials derived from PET bottles for release film, and have obtained Eco Mark certification (certification number 22118008). |

|

Feature

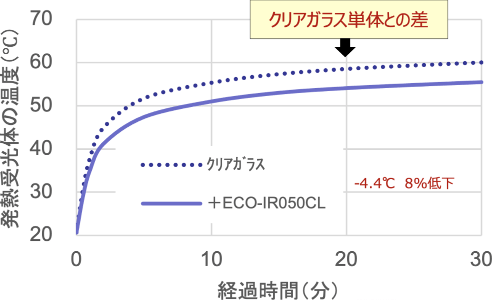

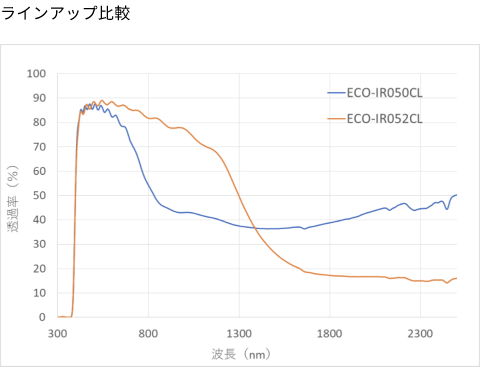

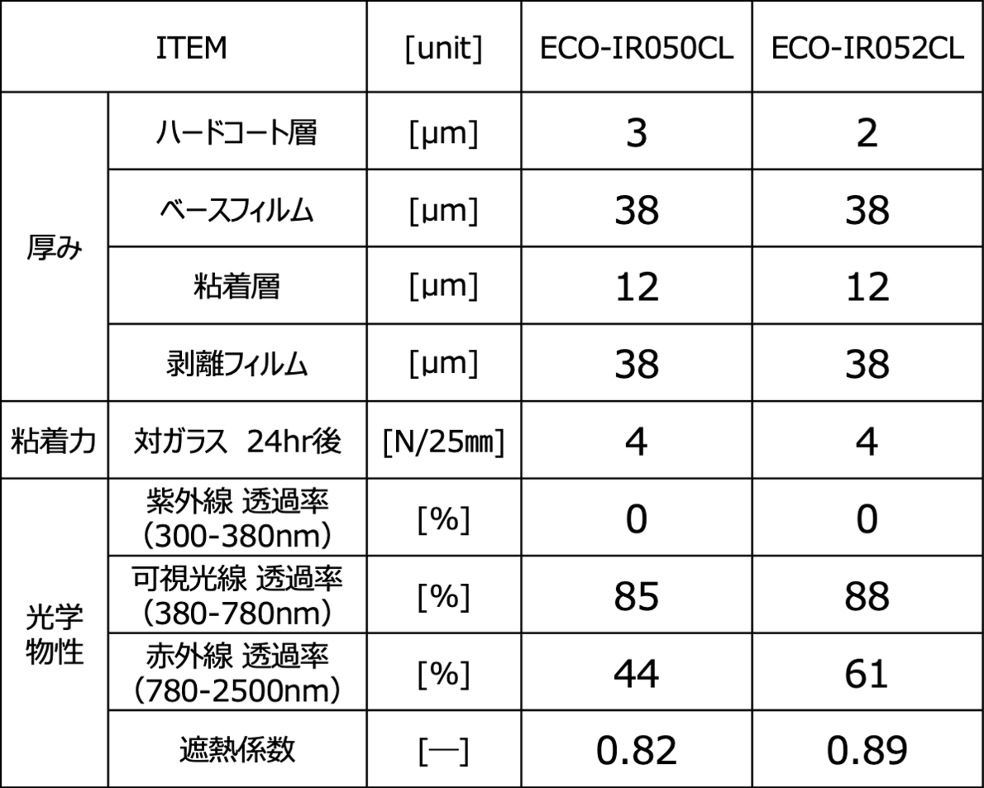

ECO-IR05xCL Series

ECO-IR050CL ・Maintains high transmittance and heat shielding properties ・Recycled PET derived from PET bottles is used as the base material for the release film.

ECO-IR052CL ・Further improvement of ECO-IR050CL’s heat shielding properties |

|

Heat shielding performance and heat resistance performance

|

JISL1951(2019) 人工太陽光源を用いた遮熱性試験 |

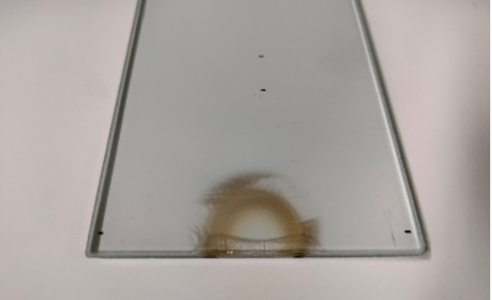

JISS3107(2013) 耐燃性試験でのサンプル画像

|

Application examples and data tables

*1:When applying window film to windshields or side shields of your car, it is necessary to meet the standards for light transmittance, including glass (Safety Standards of Road Transport Vehicle Act, Article 29, Paragraph 4) |

|

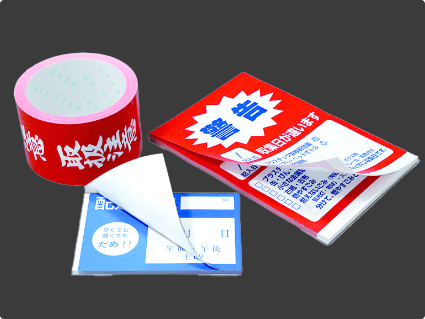

Product

“Sepa-Free, as the name suggests, is not Sepa.”

Sepa-Free series is a label product with no release paper that becomes waste.

Eco-friendly label that does not generate waste when creating and using labels.

・Lineup

Roll, Stack, Laminated, Bi-fold. We offer Sepa-Free products compatible with OA printers.

Customization in view of size, printing, and adhesive strength is available.

Depending on the work method, environment, and frequency, we will propose the most suitable type and specifications.

※Sepa-Free is a registered trademark.

Application examples

Product

Made from various fibers, conventionally disposed of as waste.

Contribute to the realization of a circular economy.

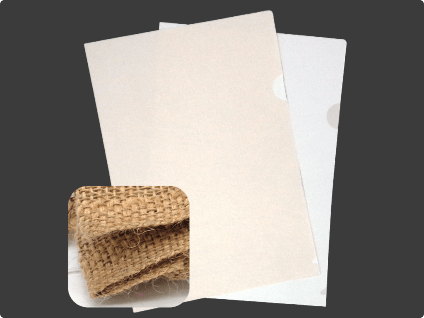

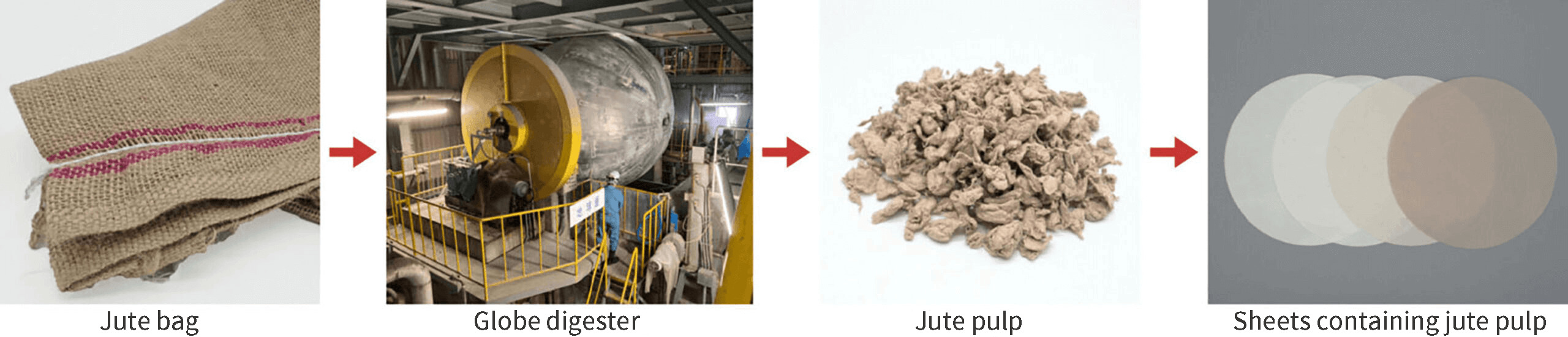

MEGURISH(jute)

MEGURISH (cotton)

Jointly developed with Kusubashi Mon-Ori Co., Ltd., a long-established towel manufacturer in Imabari City, Ehime Prefecture. Yarns and scraps generated as waste during towel production are reborn as paper.

|

||

|

thread for towels |

giftbox |

|

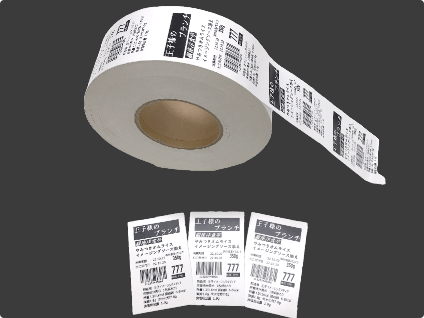

Product

Developed a thermal paper for linerless labels, which do not require release paper.

・High sensitivity, high image quality and high durability.

・Reduce environmental impact incl. CO2 emissions by no use of release paper.

Agriculture Business

Agriculture Business

The wave of environmental response is also hitting the agricultural sector, which is essential to our lives. Until now, plastic materials have been used as convenient materials in a variety of situations, but there is a need to not only reduce the amount of plastic used, but also to develop biodegradable film products and paper products that have the same functionality as film.

Product

Mainly made from cellulose. When plowed into the soil after harvest, it decomposes into soil, reducing burden of stripping and industrial waste disposal costs. Furthermore, compared to polyethylene mulch sheets, it can suppress the rise in soil temperature. Effective in reducing root rot caused by heat, and especially suitable for crops grown in summer.

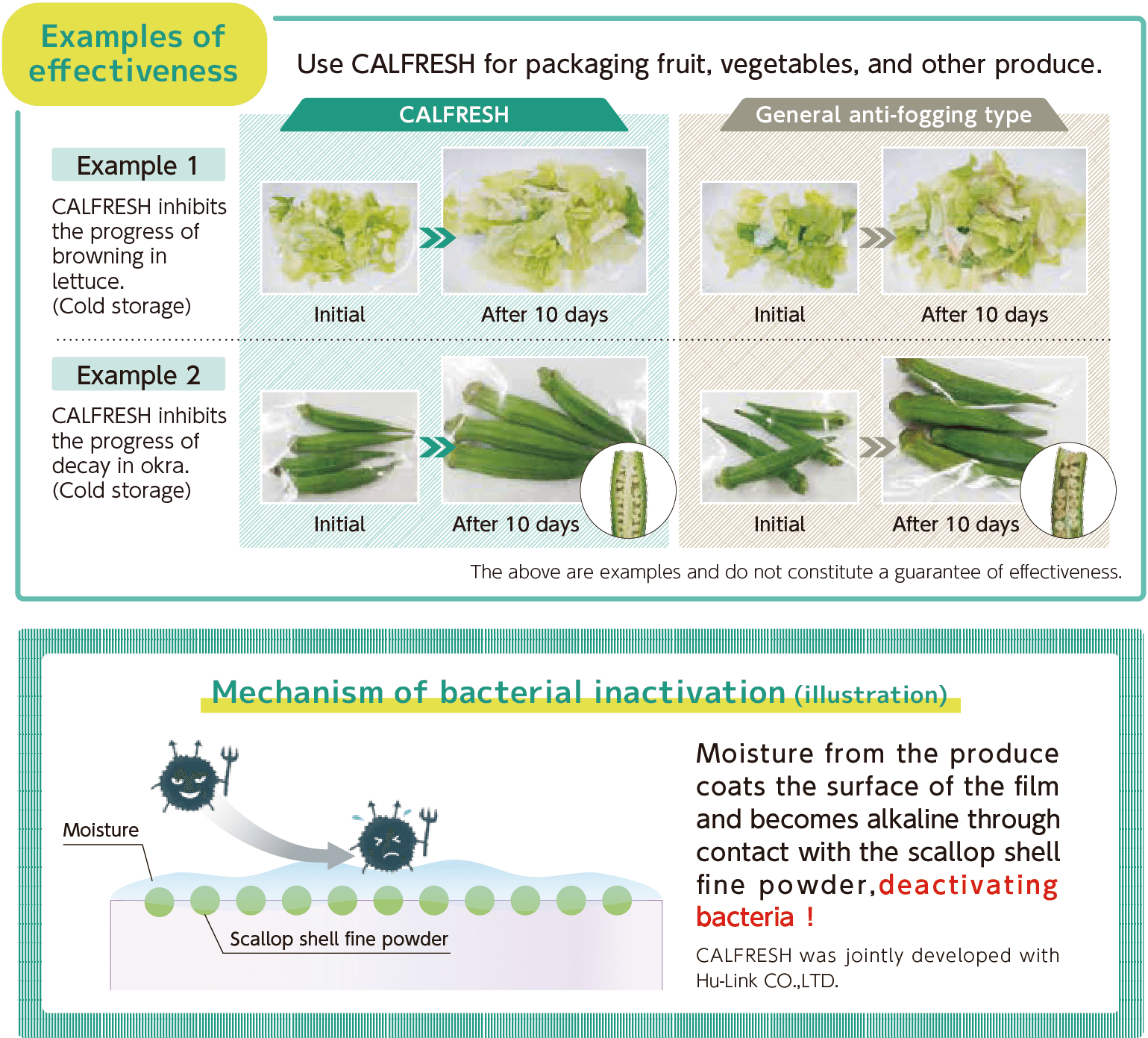

Product

OPP film containing fine scallop shell powder. Alkaline surface inactivates bacteria and prevents their growth.

Contributes to the SDGs through utilization of scallop shells, which are disposed of as wastes in Japan, and food loss reduction by inactivating bacteria.

Feature

By reducing waste, CALFRESH contributes to the achievement of the SDGs.

・Utilizes scallop shells that are normally handled as industrial waste

・Deactivation of bacteria reduces food loss

Lineup

30 μm thickness is suitable for produce packaging

Please inquire regarding other thicknesses.

Effectiveness

Product

Eco-friendly pulp nonwoven fabric with biodegradability and water-degradability.

・Thickness, excellent water-absorption.

・large water-retaining and very large inner voids allowing plants to root well.

・good shock absorption and damage prevention properties.

・disposable as a burnable waste.

Good for use in a wide range of applications, incl. agricultural materials, toilet cleaning sheets, cushioning and packaging materials, and base materials (puffs) for hygiene and cosmetic applications.

Product

Freshness preservation sheet, made of natural pulp and antibacterial agent of calcined scallop shell powder.

Simply placing the sheet under cherry tomatoes in the cardboard box suppresses moisture condensation on tomatoes’ surfaces and prevents them from cracking.

Even if cracking occurs, the sheet absorbs liquid and inhibits mold.

Especially effective during hot and humid summer, functioning as a cushioning material.

Other recommendation

Other recommendation

Product

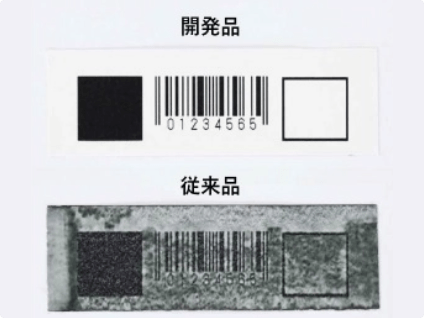

Thermal paper with excellent alcohol resistance, superior durability compared to conventional ones.

・No color change or go off when exposed to alcohol.

・Higher resistance to other solvents, which enable us to enter new fields.